Standard 3D Scanning Service

Efficient Model Reconstruction — Accelerate Your Digital Workflow

Contact Us

Standard 3D Scanning Service

Overview

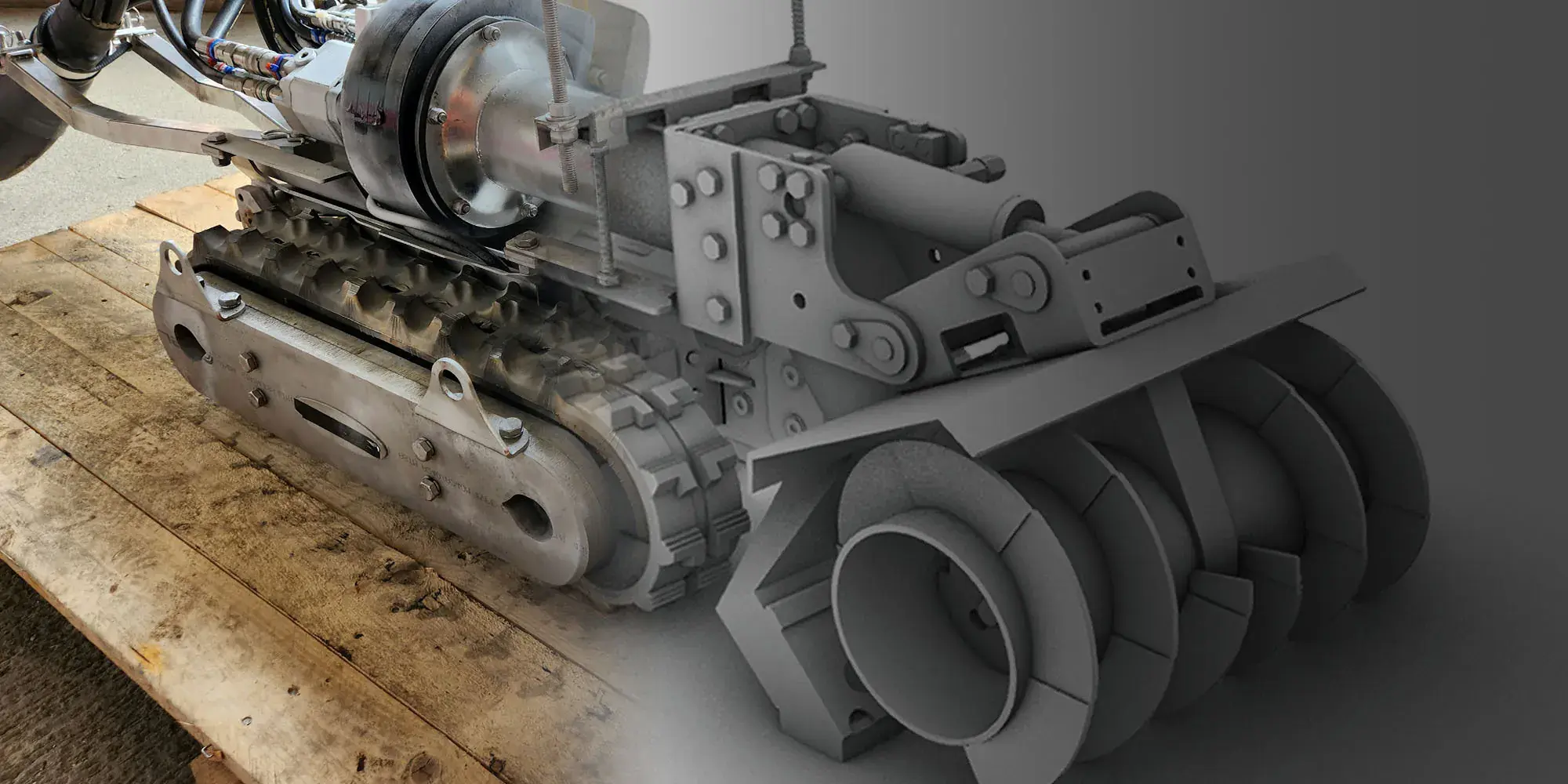

Standard 3D scanning provides a fast and accurate method for capturing the three-dimensional data of physical objects. It is an essential tool in product design, quality inspection, and prototype development. Whether for small to medium components or complex geometries, professional scanning equipment enables precise digital processing to generate high-accuracy models. The resulting data can be directly applied to CAD design, 3D printing, CNC machining, or reverse engineering, helping to shorten development cycles, enhance design precision, and reduce production risks. This service is ideal for businesses and individuals requiring long-term data preservation or subsequent modification, serving a wide range of applications across industrial, research, and educational fields.

Discover Our Core Strengths

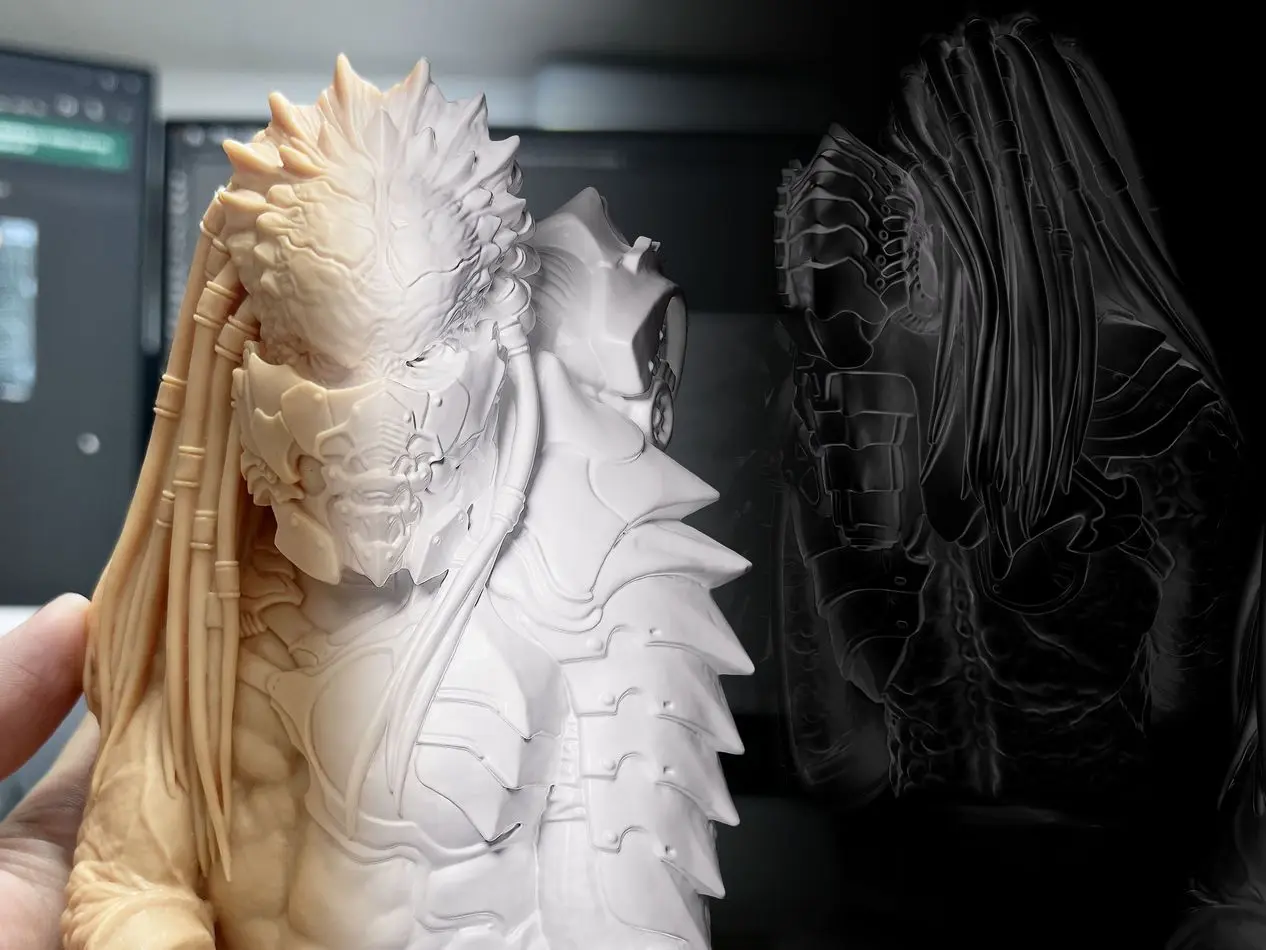

Precision Capture

Utilizing high-accuracy 3D scanning technology, we capture complete geometric shapes and fine surface details with exceptional precision

regardless of size or structural complexity ensuring reliable and accurate data output.

Efficient Workflow

Our process enables rapid data acquisition, allowing scanned models or parts to be digitally repaired and modified directly on the computer. This streamlines design and manufacturing, supports faster iteration, and reduces overall time and cost.

Versatile Applications

3D scanned models can be visualized, edited, and used across digital platforms — including VR, AR, and animation — providing flexibility for creative and technical applications.

Simple Five-Step Scanning Process

1

Object Evaluation

Assess the object’s size, material, and precision requirements to determine the most suitable scanning solution.

2

Surface Preparation

For reflective or transparent materials, surface treatment or powder coating is applied to ensure scanning accuracy.

3

Data Scanning

Capture complete geometric data and surface details using high-precision 3D scanners.

4

Data Processing

Clean, align, and reconstruct point cloud data to generate a complete 3D model.

5

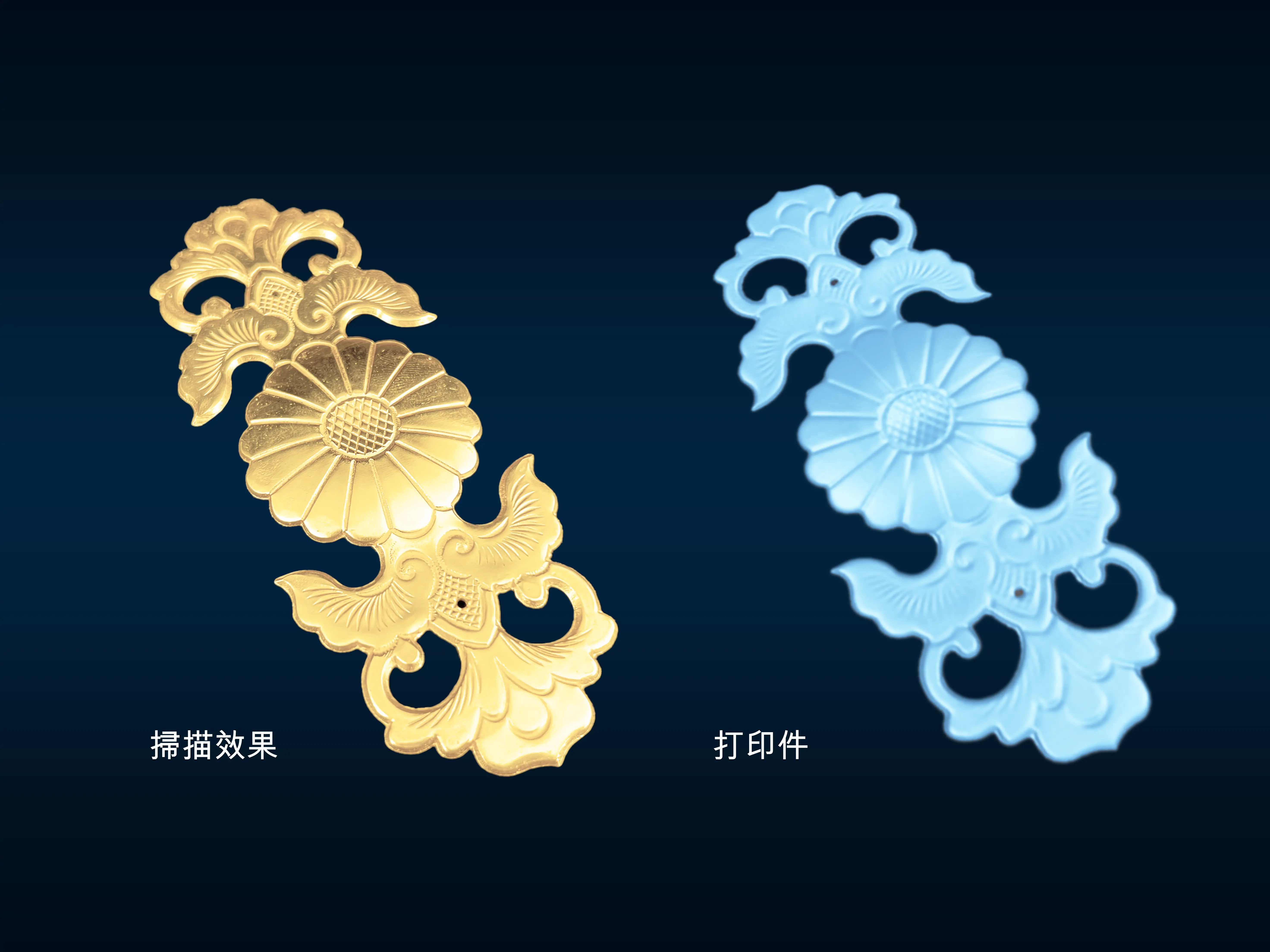

Model Output

Export the model in formats such as STL, OBJ, or PLY for use in design, 3D printing, or visualization.

Precision & Rapid 3D Scanning

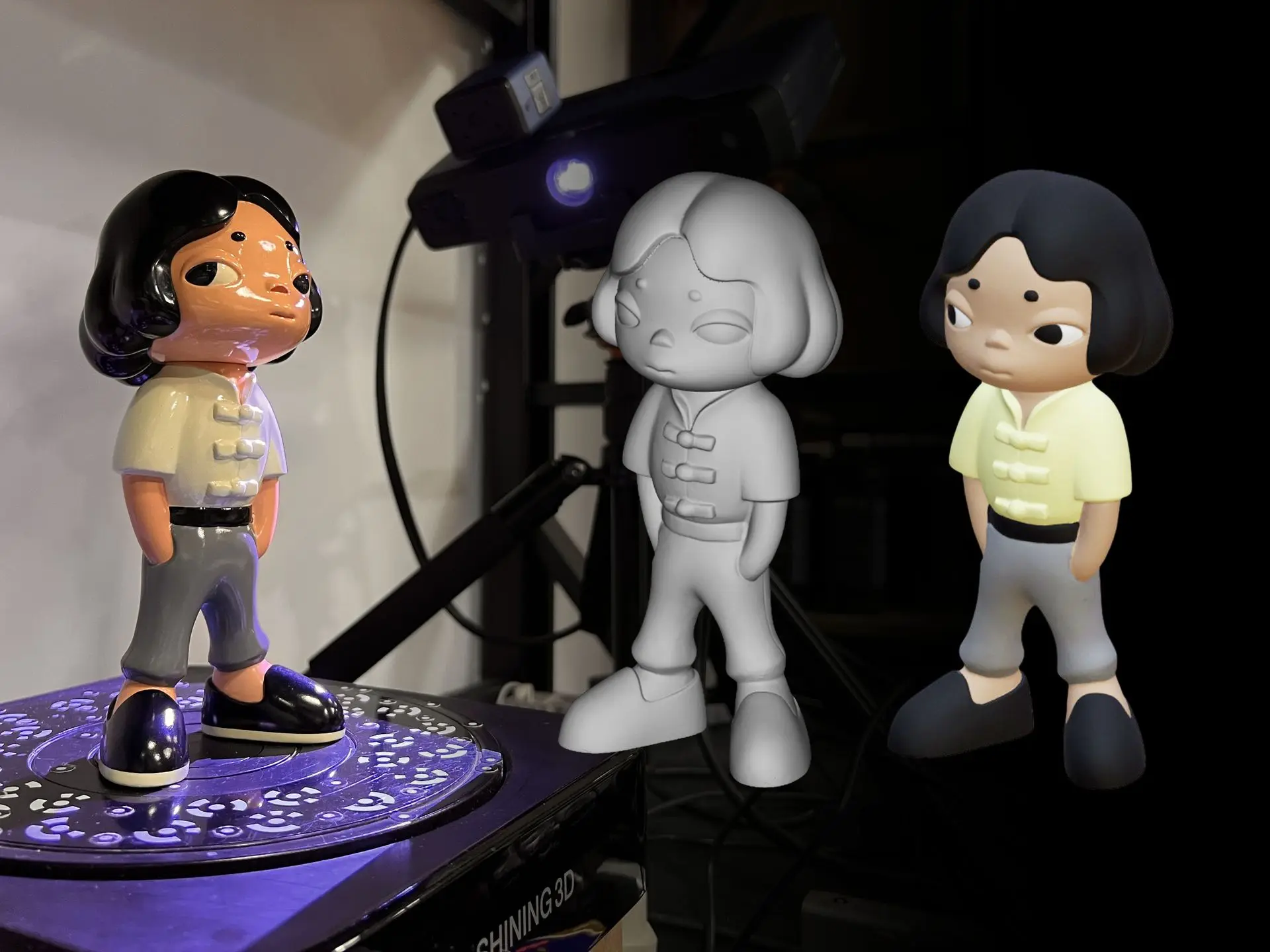

Standard Scanning Data Processing Options

(Pricing varies by model complexity, starting from HKD 200.)

Option 1

Receive the raw scan file after scanning (.STL / .OBJ / other formats).

Option 2

Request additional file modification or digital processing according to your specifications.

Option 3

For items that cannot be scanned, our technicians perform manual precision measurement.

Option 4

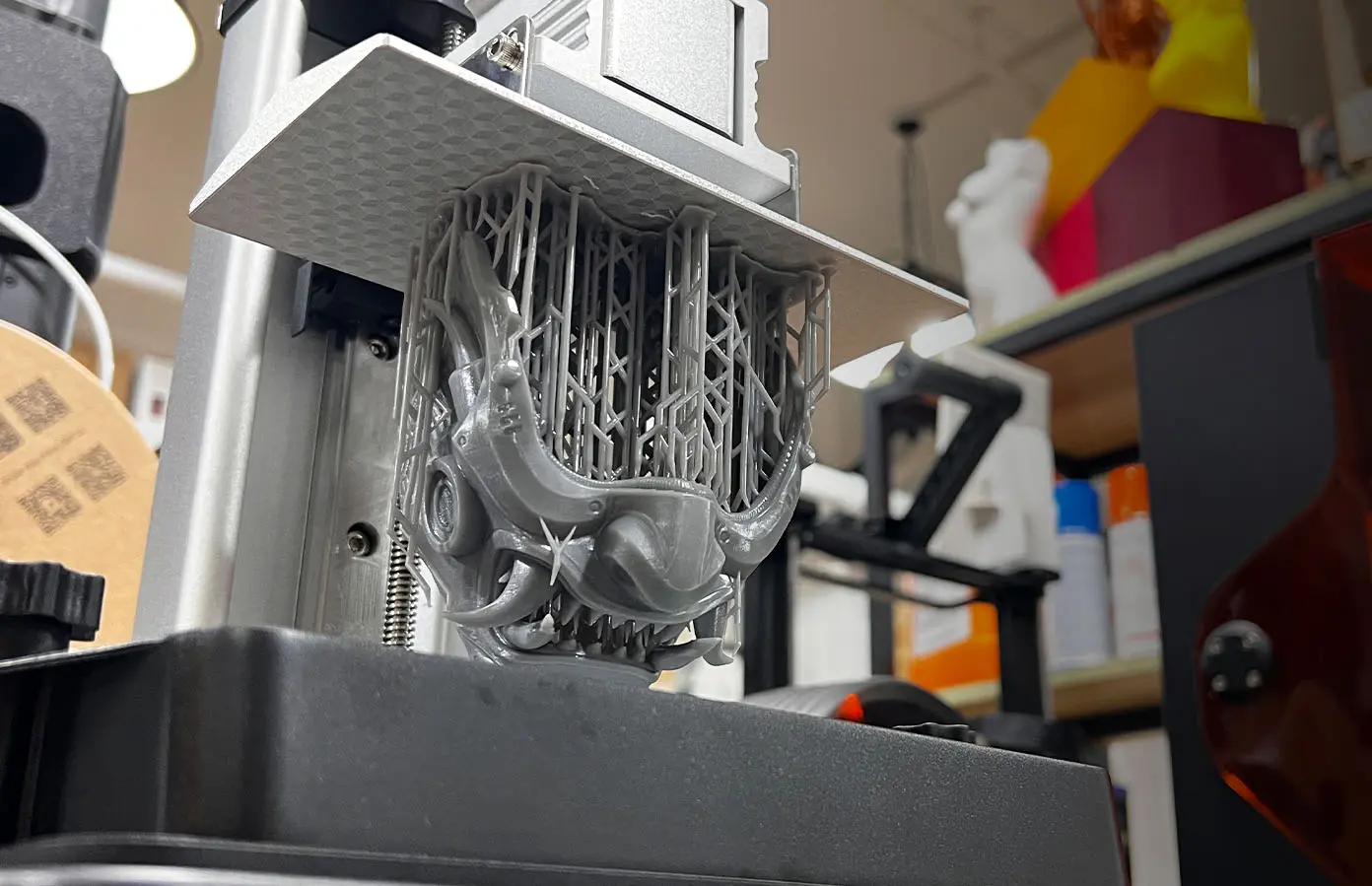

Obtain both the digital file and the 3D printed output produced from the scanned model.

Scanning Guidelines

To ensure a smooth and accurate scanning process, please note the following:

Provide Reference Photos and Dimensions

Send multi-angle photos and approximate size for a quick quotation.

Size Limitations

Minimum object size: 5 cm³. Contact us for special cases.

Object Color

Black, transparent, or reflective items need powder coating for best results.

Tailored Solutions for Every Need

With our comprehensive experience in design and manufacturing, AIO STUDIO delivers efficient and reliable solutions that turn your creative ideas into tangible results.

We are committed to helping businesses and brands achieve high-quality, professional outcomes — quickly and effectively.

Contact us today to learn more.

Frequently Asked Questions

The standard turnaround time is 7–10 working days. Express service is available — if the object is received before 12:00 PM, it can be completed by 8:00 PM on the same day. Please inform us in advance if urgent service is required.

如有任何疑問,歡迎隨時向我們查詢。

Maximum size: 60 mm × 60 mm × 60 mm

Minimum size: 10 mm × 10 mm × 10 mm

Because 3D scanners rely on optical sensing, black, transparent, and reflective objects are difficult to scan.

-Black absorbs light

-Transparent materials allow light to pass through

-Reflective surfaces cause unwanted glare

-To ensure accuracy, we recommend applying 3D scanning spray, which evaporates naturally after a few hours.

Objects with internal cavities, hollow structures, or holes deeper than 5 mm may result in missing data, as light cannot reach those areas. The final file will appear as a solid 3D model without color texture.

Yes — as long as the scan data is complete and free of missing surfaces, it can be printed directly.

3D scanning is widely applied across architecture, automotive, toy and model making, ceramics, electronics, animation, film production, art installations, urban planning, and virtual reality.

Related Services

3D Printing Services

Transforming creativity through technology bringing your ideas to life.

View Details

Reverse Engineering Services

Converting real-world objects into precise digital models for further development.

View Details