High-Precision Jewelry-Grade 3D Scanning

Capturing micron-level detail — revealing the true beauty of craftsmanship.

Contact Us

High-Precision Jewelry-Grade 3D Scanning

Overview

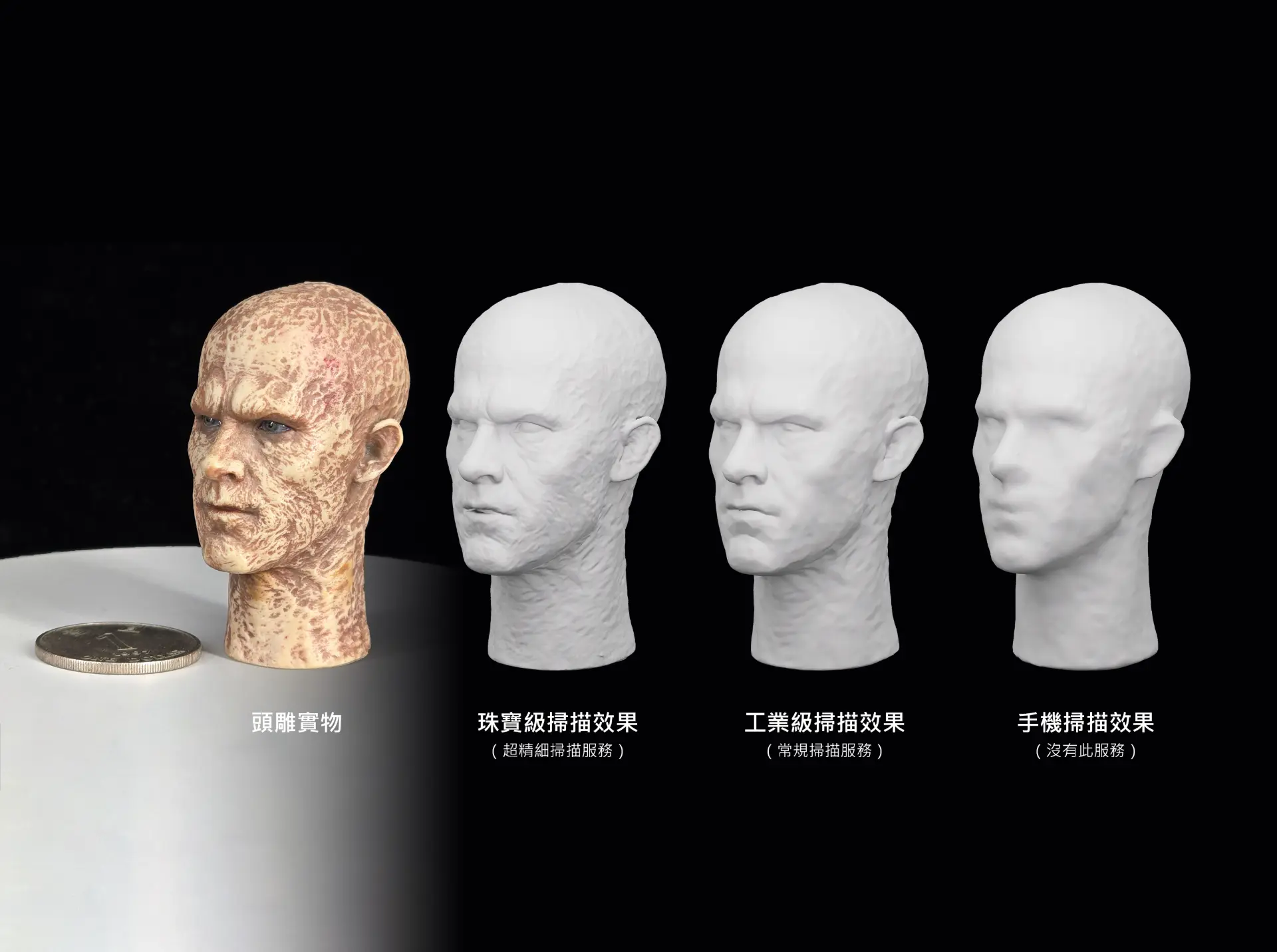

Our high-precision 3D scanning service delivers exceptional accuracy and resolution, enabling significant improvements in design efficiency, production speed, and product quality. From toy figures and engineering development to the jewelry industry, our advanced scanning solutions help clients gain a competitive edge through enhanced productivity and precision.

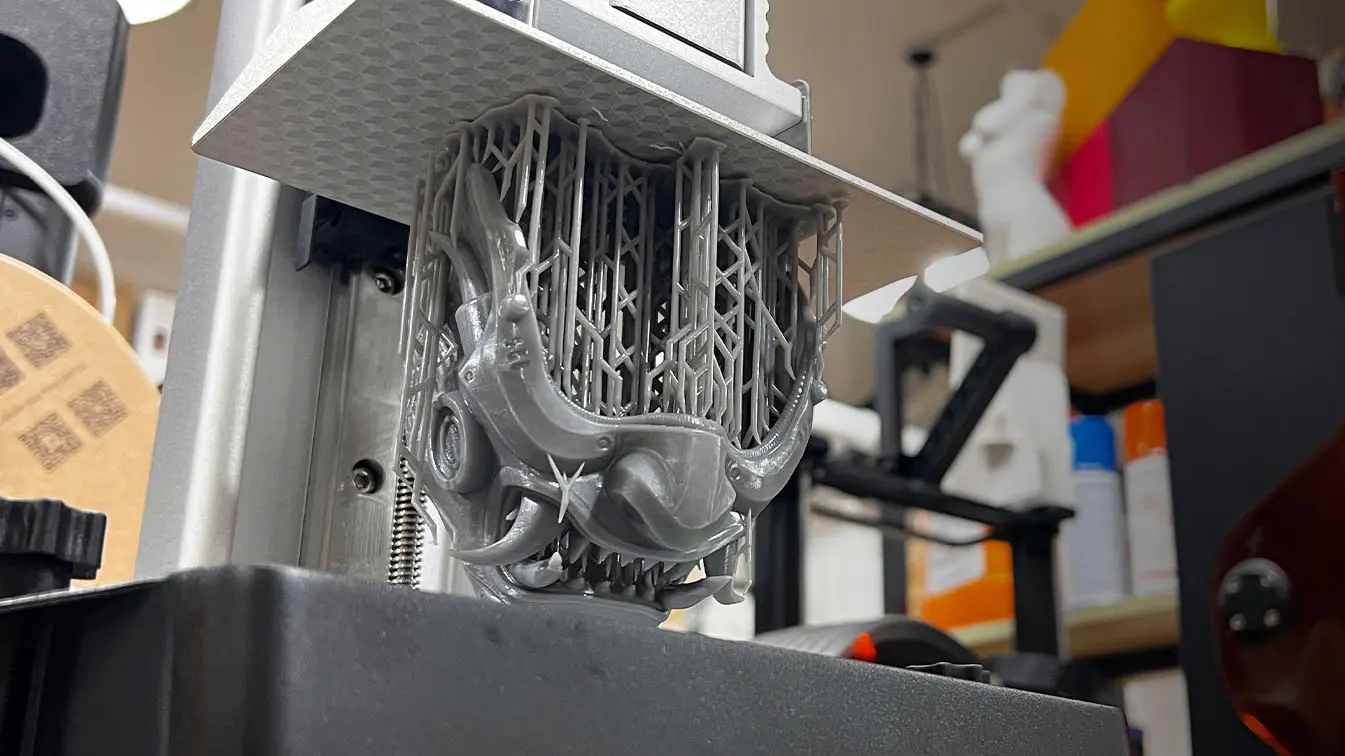

Past Scanning Results

Case 1

案例二

Frequently Asked Questions

The standard turnaround time for 3D scanning is 7–10 working days. Express service is available — if the object is received before 12:00 PM, it can be completed by 8:00 PM on the same day. Please notify us in advance for urgent requests. For any inquiries, feel free to contact us.

This high-precision 3D scanning service is specifically designed for small and intricate components, capturing fine details with exceptional clarity.

- Maximum size: 60 mm × 60 mm × 60 mm

- Minimum size: 1 mm × 1 mm × 1 mm

Since 3D scanners rely on optical reflection, black, transparent, and reflective objects cannot be accurately scanned.

Black surfaces absorb light. Transparent materials allow light to pass through. Reflective surfaces cause glare and distortion. To ensure optimal results, we recommend applying a 3D scanning spray, which evaporates naturally within a few hours.

Objects with internal cavities, hollow areas, or holes deeper than 5 mm may not be fully captured, as light cannot reach those regions. The final scan file will appear as a solid 3D model without color data.

Yes — if the scan data is complete and free of missing surfaces, it can be directly printed.

Case 1

你的旅程,從這裏開始

解決方案專為你設計,讓每一刻都有實際效果。

創新理念

我們的所有工作都以創意為先,提供創新的解決方案,使你的專案項目表現出眾,同時保持原創性與功能之間的平衡。

全面支援

從初始階段到完成,我們在途中每一步都為你提供支援,確保你對自己的選擇有信心,並確保你的專案項目取得成功。

品質歷久常新

我們的服務效用持久,確保我們提供的每一套解決方案,都是最高質素,為你的投資創造長久價值,最終讓客戶滿意。

Related Services

Laser Cutting Services

High-accuracy cutting and engraving for flawless presentation of your designs.

View More