Reverse Engineering

Transforming real-world objects into precise digital models — rebuilding your creativity step by step.

Contact Us

Reverse Engineering

Introduction

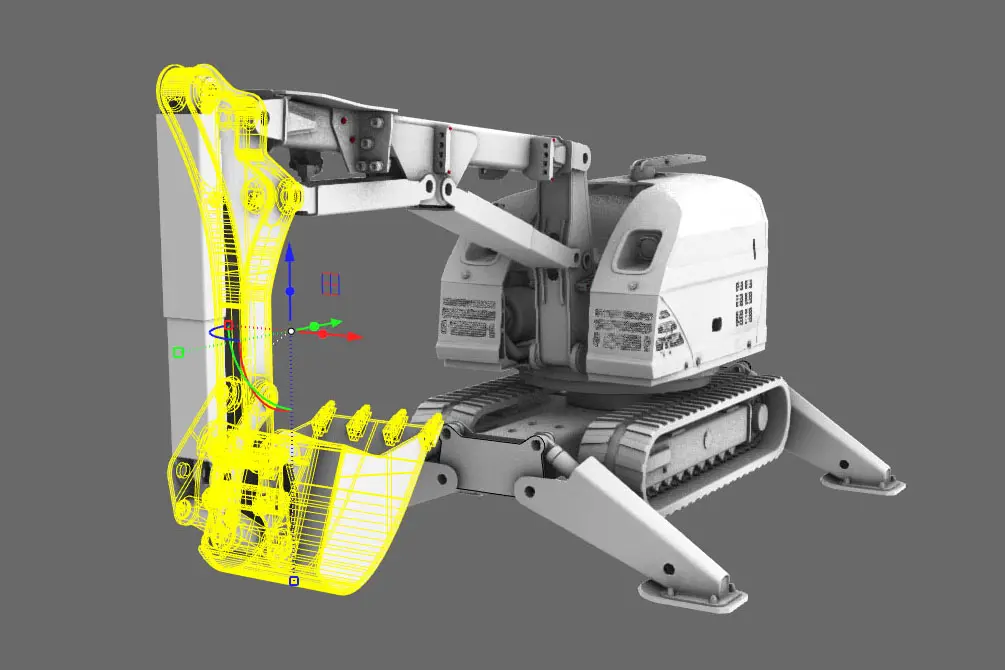

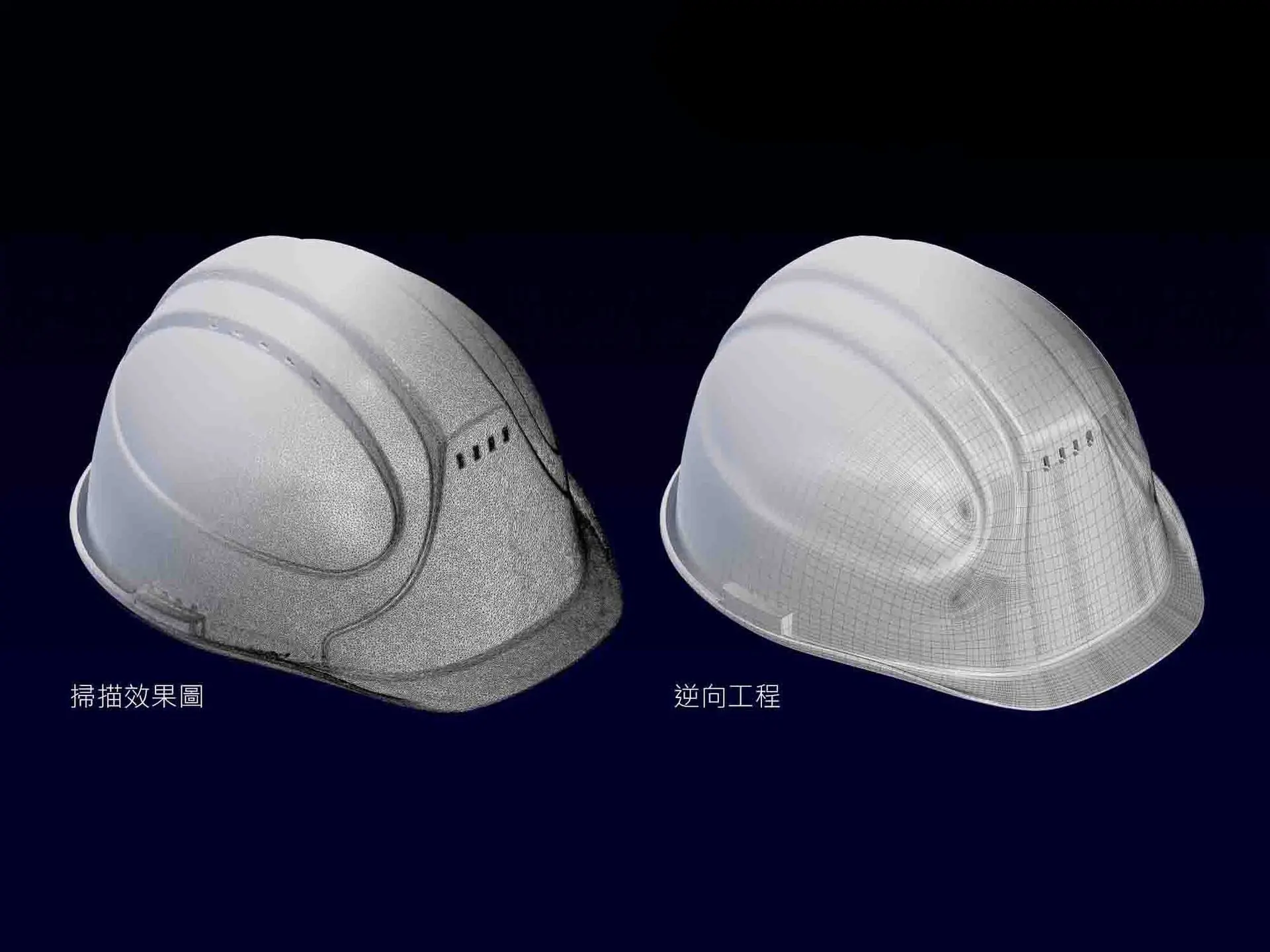

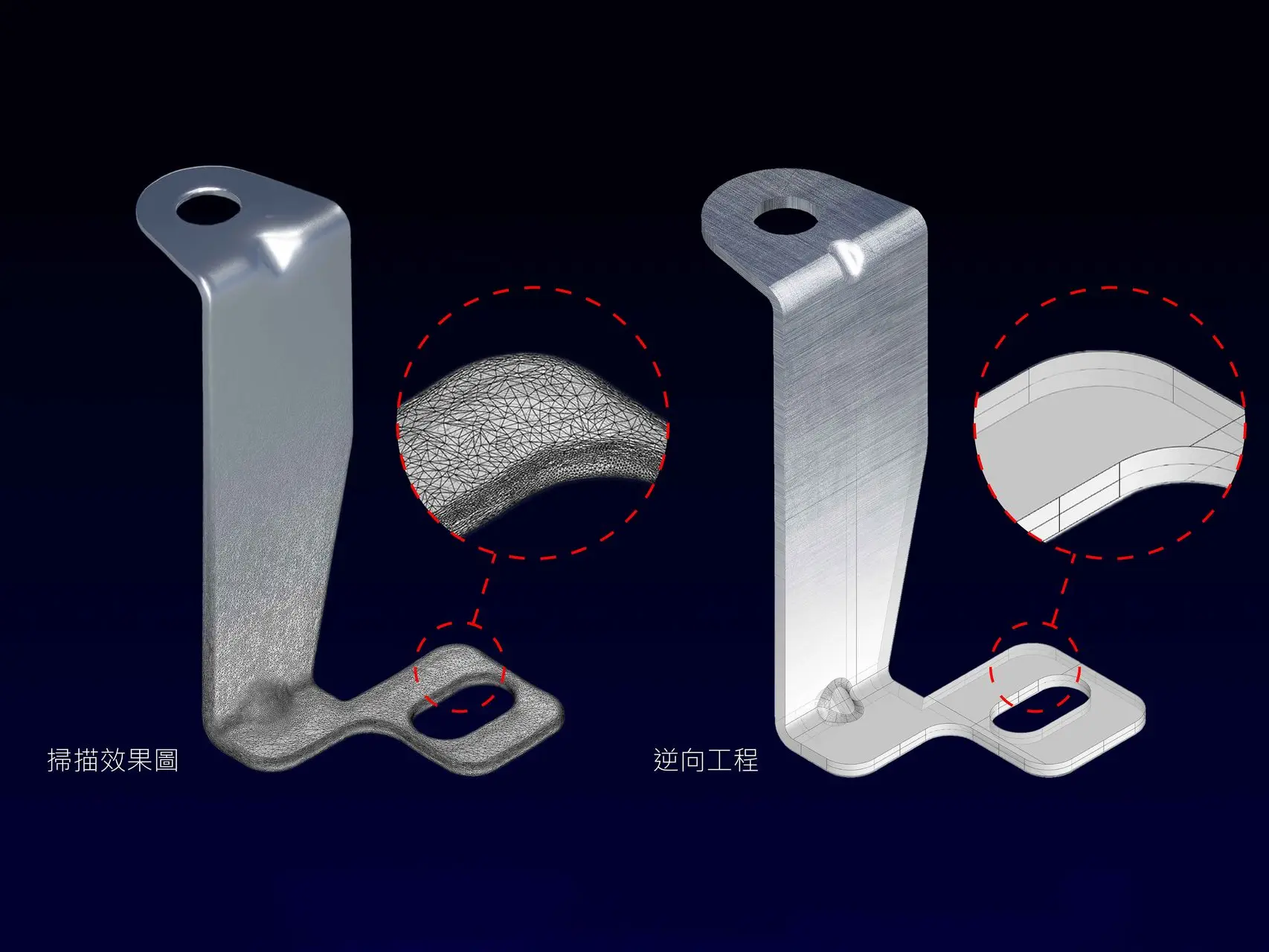

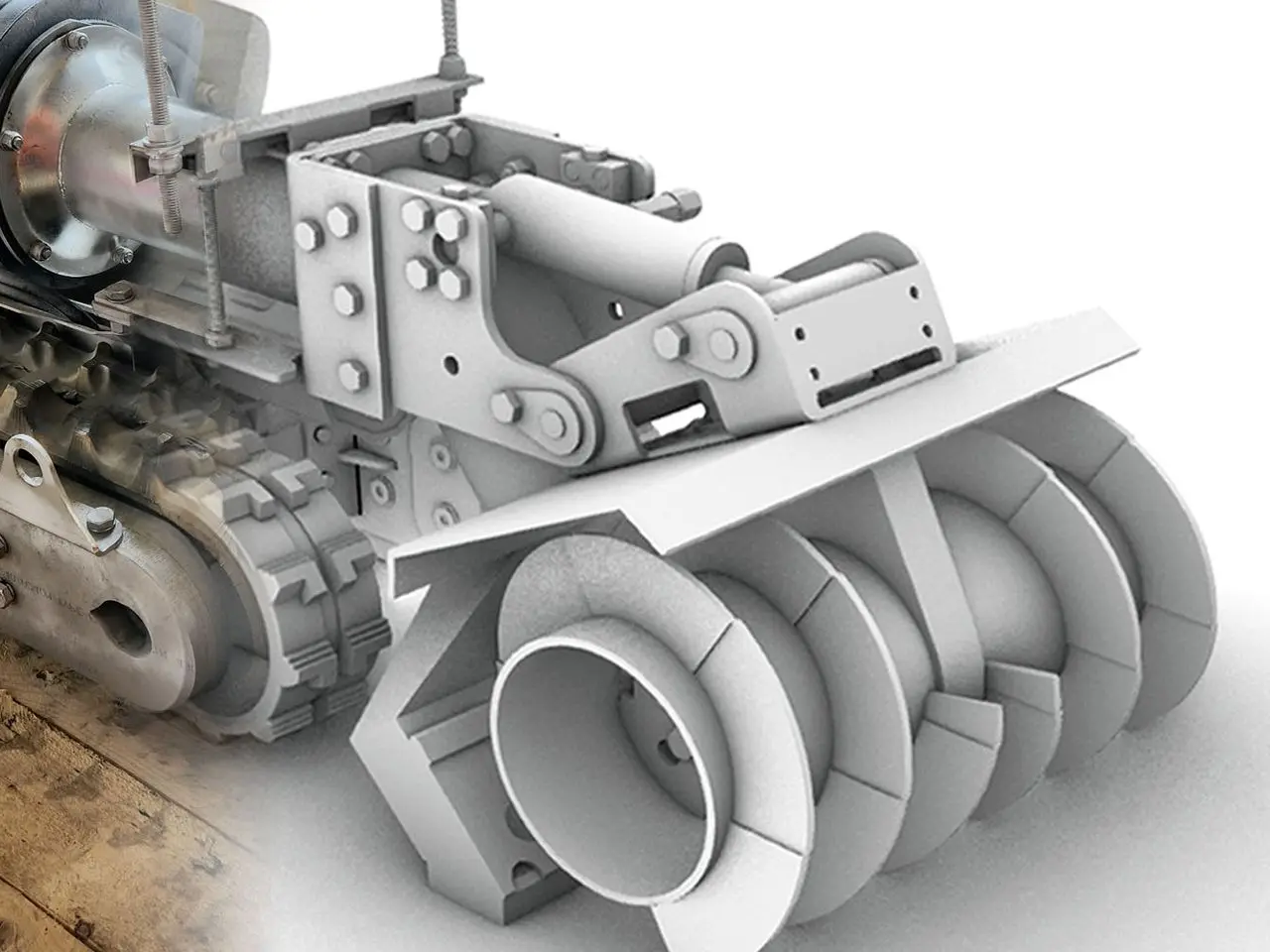

Reverse engineering integrates 3D scanning with professional modeling to transform physical objects into fully editable CAD models. Through this process, legacy parts can be redesigned, repaired, or enhanced, enabling direct use in CNC machining, 3D printing, or mold fabrication. This service is particularly valuable for component restoration without original drawings, product upgrades, or competitor analysis. High-precision data conversion ensures industrial-grade accuracy while significantly reducing development and reproduction time. Whether for industrial components, mechanical equipment, or product housings, reverse engineering provides strong support for both design and manufacturing.

Discover

Our Three Key Advantages

Data Reconstruction

Transform physical objects into precise CAD data through scanning and modeling — allowing easy design modification, part replication, and product enhancement.

Precision Modeling

Output data meets industrial-grade standards, supporting structural inspection, detailed engineering design, and high-precision manufacturing — ensuring professional quality and reliability.

Process Integration

The generated models can be directly applied to CNC machining, 3D printing, or mold fabrication — seamlessly integrating with manufacturing workflows and shortening development cycles.

Five Steps to Complete the Process

1

3D Scanning

Capture the object’s geometry and fine details using high-precision 3D scanning equipment.

2

Data Processing

Clean noise from the point cloud and align multiple scan sets for accurate reconstruction.

3

Surface Reconstruction

Convert the point cloud into editable CAD surfaces or solid models.

4

Model Refinement

Adjust dimensions, repair structures, and optimize the model according to project requirements.

5

Output & Application

Export in formats such as STEP or STL for design, manufacturing, or analysis purposes.

Reverse Engineering

Redraw precise CAD models based on 3D scan data — a specialized service designed for clients who require .STP or other professional CAD formats.

專為要.stp/其他格式的客人而設

Frequently Asked Questions (FAQ)

Reverse engineering is a process that starts from a physical object, using 3D scanning or measurement to capture its data and convert it into an editable 3D digital model. This technique enables detailed analysis, modification, and redesign of existing items, and is widely used in product development, restoration, and improvement.

Reverse engineering is ideal when original design drawings are unavailable, replacement parts need to be fabricated, existing products require enhancement, or when analyzing structures and reproducing legacy items. It is commonly applied in fields such as mechanical components, artwork restoration, mold design, and prototype fabrication.

We can export in multiple formats, including .STEP, .IGES, .STL, and .OBJ, ensuring compatibility with CAD software such as SolidWorks, Rhino, Fusion 360, and others.

While 3D scanning focuses on capturing surface geometry and visual details, reverse engineering converts that data into editable, manufacturable CAD models — allowing for precise measurement, modification, and redesign.

Yes. The finalized model can be applied directly to CNC machining, 3D printing, or injection mold design, ensuring dimensional accuracy and consistent production quality.

Simply provide a physical sample or existing 3D scan data (if available). If scanning is required, we will assess and quote based on the object’s size, material, and precision requirements.

The turnaround time depends on project complexity. Standard projects typically take 3–5 working days, with expedited service available upon request. Please contact our team for detailed arrangements.