SLA Photopolymerization

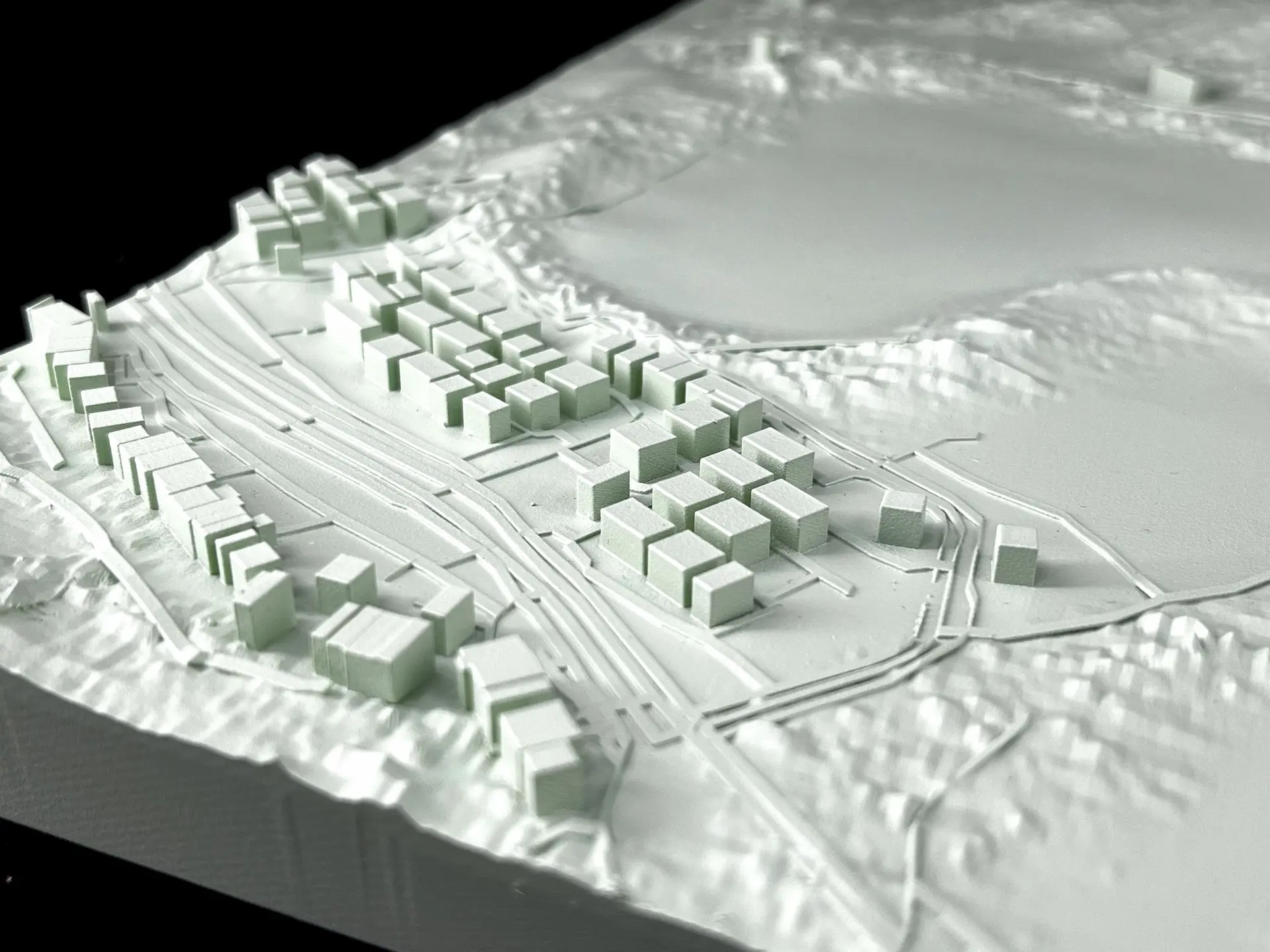

SLA (Stereolithography) utilizes ultraviolet light to cure liquid resin, producing models with exceptional precision and smooth surface finishes. It is ideal for rapid prototyping and visual presentation purposes.

Standard Resin (White)|High-Temperature Resin (Grey)|Tough Resin (Yellow)|Transparent Resin (Matte/Clear)

Advantages

- High Precision & Smooth Finish Layer thickness as fine as 0.1–0.2 mm delivers detailed and refined surfaces. Minimal post-processing is required, making it suitable for display models and aesthetic verification.

- Cost-Effective Production Resin materials are relatively affordable, enabling fast and efficient production of visual prototypes for preliminary design evaluation and concept presentation.

- Versatile Applications Ideal for toys, props, industrial design models, and architectural prototypes where surface detail and visual accuracy are essential.

LCD Photopolymerization

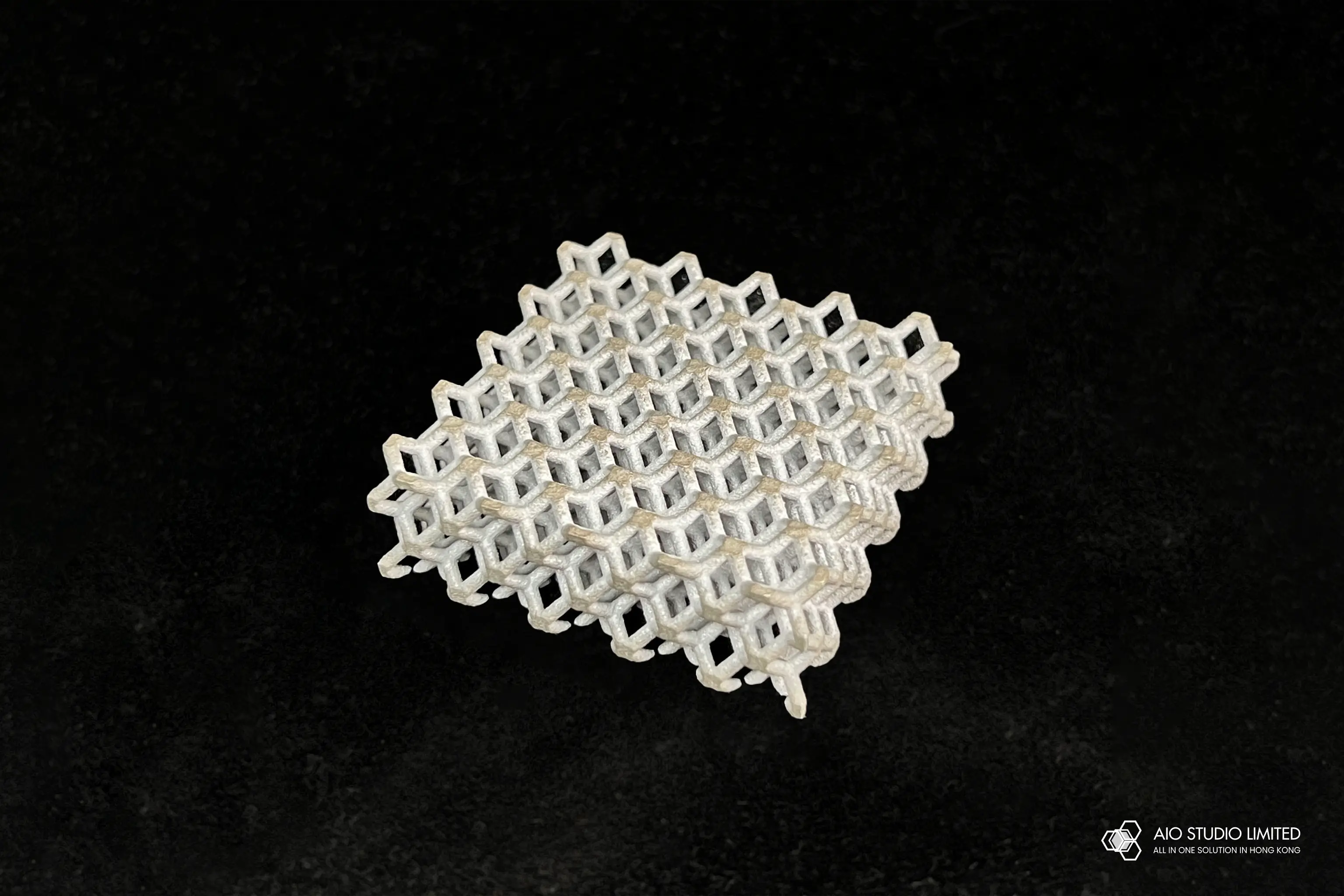

LCD photopolymerization employs a high-resolution LCD screen to cure resin layer by layer, achieving exceptional detail accuracy and surface quality. It is particularly suitable for intricate models and artistic sculptures.

Standard Model Resin (Grey)|Nano-Ceramic Resin (Terracotta Red)|Wax-Like Resin (W20 Green / W40 Orange)|High-Transparency Resin (Matte Finish)

Advantages

-

Exceptional Detail Reproduction

With layer thickness as fine as 0.03–0.05 mm, LCD printing captures intricate textures and fine details — ideal for figurines, miniature sculptures, and precision crafts.

-

Rapid Turnaround

Locally produced for urgent orders, with same-day or 1–2-day delivery available.

-

For Both Art & Engineering Applications

Equally suitable for high-fidelity art pieces and functional prototypes used in design verification or mechanical testing.

FDM (Fused Deposition Modeling)

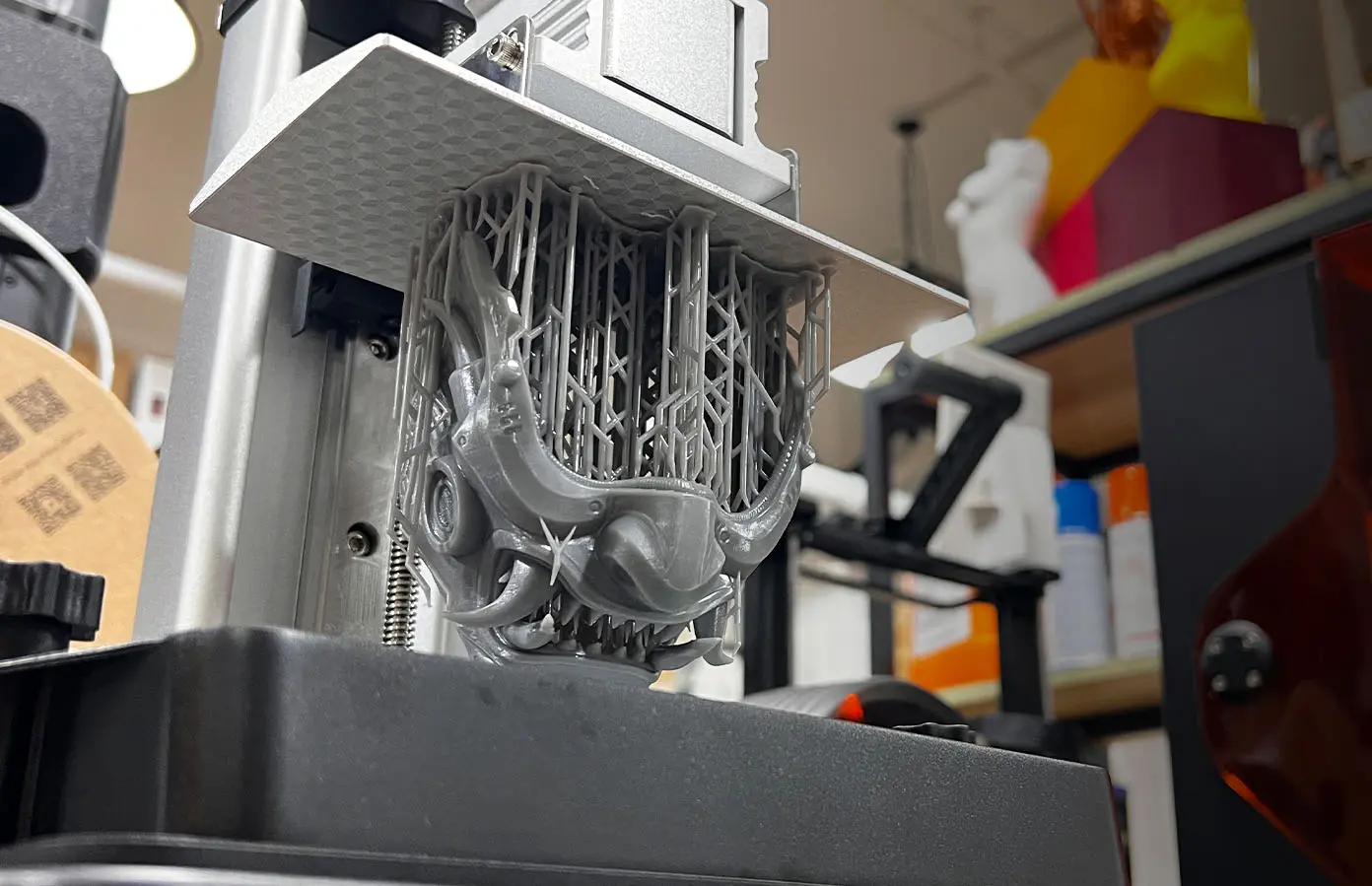

FDM technology extrudes thermoplastic materials layer by layer to build parts with excellent durability and cost efficiency. It is ideal for functional prototypes and end-use components.

PLA (Multicolor Options)|PETG (Black / White / Grey / Marble)|Others (Contact Us for More Options)

Advantages

-

Cost-Effective Solution

Common materials such as PLA and PETG offer an affordable option for low-cost prototyping and design testing.

-

Durable Structure

While surface texture is relatively rougher, the parts exhibit excellent mechanical strength — suitable for functional components, industrial parts, and educational models.

-

Wide Material Selection

A broad range of colors and material properties available — from transparent to rigid and flexible — providing high adaptability for diverse project needs.

SLS (Selective Laser Sintering)

SLS technology uses a high-powered laser to sinter nylon powder into solid parts, producing components with excellent mechanical strength and thermal resistance. No support structures are required, making it ideal for engineering and mechanical applications.

PA6 Nylon (White)

Advantages

-

High Strength & Heat Resistance

Nylon powder parts exhibit superior toughness and can withstand wear, impact, and elevated temperatures.

-

No Support Structures Required

During sintering, the surrounding powder naturally supports the model, allowing greater design freedom for complex geometries.

-

Ideal for Engineering & Small-Batch Production

Commonly used for functional testing parts, casings, and mechanical assemblies requiring durability and precision.

MJF (Multi Jet Fusion)

MJF technology utilizes jet fusion to produce nylon parts with excellent mechanical strength and fine surface detail. It is ideal for small- to medium-batch production with high consistency and efficiency.

PA12 Nylon (Black)|PA12GB Nylon (Black, Glass-Bead Reinforced)

Advantages

-

Superior Surface Uniformity

Finished parts feature smoother surfaces and consistent color tones, achieving an appearance comparable to injection-molded components.

-

Excellent Mechanical Performance

Nylon materials deliver high strength and thermal resistance, suitable for demanding engineering applications.

-

High Production Efficiency

Optimized for small- to medium-scale manufacturing with short lead times, enabling rapid fulfillment of multiple parts simultaneously.

SLM (Selective Laser Melting)

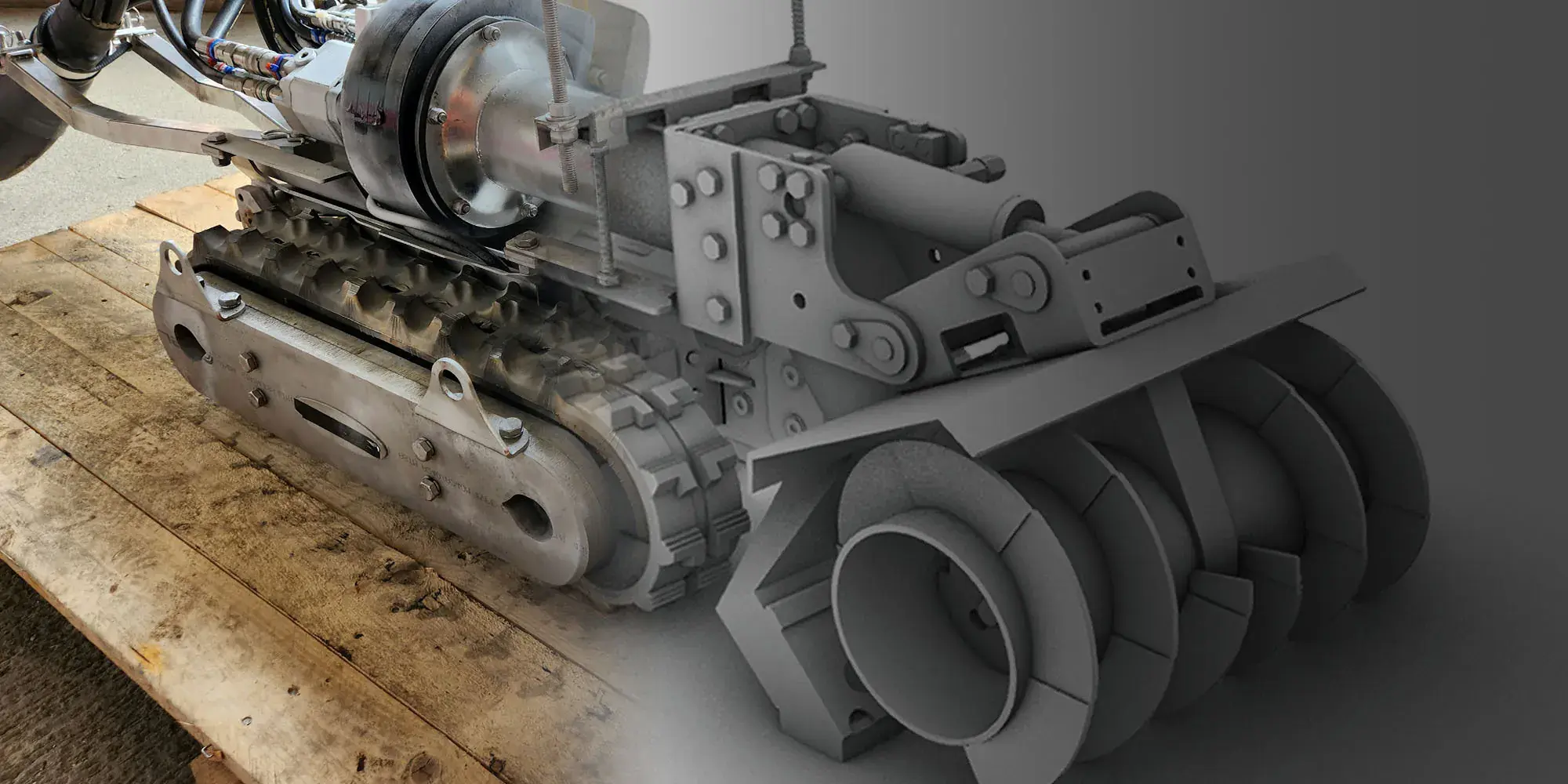

SLM technology uses a high-powered laser to fully melt and fuse metal powder, producing components with exceptional strength and precision. It is widely applied in aerospace, medical, and industrial fields.

316L Stainless Steel (Metallic Finish)|Aluminum Alloy (Metallic Finish)

Advantages

-

High-Strength Metal Components

Utilizing materials such as 316L stainless steel, SLM enables the direct production of durable, industrial-grade metal parts.

-

Designed for Demanding Environments

Corrosion- and heat-resistant, suitable for aerospace, medical, and automotive applications requiring high performance under extreme conditions.

-

Complex Metal Structures

Capable of producing intricate geometries — such as hollow components and cooling fins — that are difficult or impossible to achieve through traditional machining.

PolyJet Full-Color Printing

PolyJet technology jets multiple resin materials simultaneously, enabling full-color and multi-material printing with exceptional precision. It is ideal for display models, design prototypes, and product visualization.

Standard Resin (Color Output Based on 3D Model Data)

Advantages

-

True Full-Color Output

Capable of directly producing vivid, full-color models — perfect for presentation samples and visual design validation.

-

Multi-Material Integration

Combines rigid and flexible materials, or transparent and opaque effects, within a single print for enhanced design versatility.

-

High-Definition Surface Quality

Delivers extremely smooth surface finishes suitable for display, presentation, and client approval without additional post-processing.

TPU Flexible Overmolding

TPU (Thermoplastic Polyurethane) is a highly elastic and durable material commonly used for producing flexible parts. It offers excellent abrasion resistance, impact strength, and long-term flexibility.

Standard TPU (Black / White)

Advantages

-

High Flexibility & Elasticity

Capable of withstanding bending and stretching, ideal for producing soft components that require durability and repeated use.

-

Abrasion & Impact Resistance

More durable than conventional plastics, making it suitable for protective casings and cushioning parts.

-

Wide Range of Applications

Used in insoles, flexible joints, phone cases, and medical products requiring both softness and resilience.