On-Site 3D Scanning Service

Instant Detail Capture, Mobile & Efficient Scanning Solutions

Contact Us

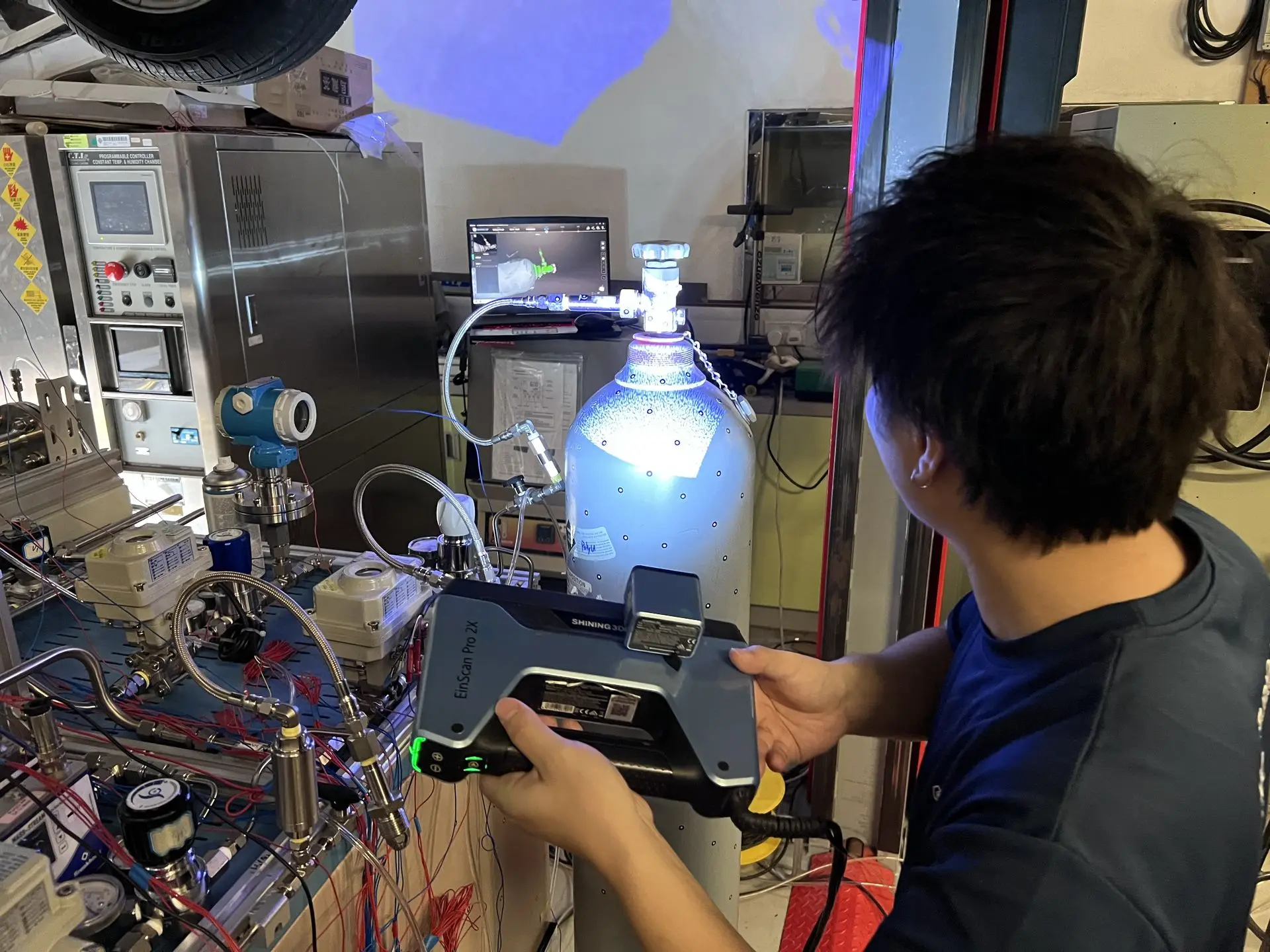

On-Site 3D Scanning Service

Overview

Our on-site scanning service is designed for large or immovable objects and environments.

Our professional team brings high-precision 3D scanning equipment directly to your location, handling architectural components, sculptures, exhibition pieces, or special installations with care.

This service eliminates the inconvenience and risk of transporting fragile or bulky items, enabling immediate data capture and real-time quality inspection on site.

It’s ideal for museums, art studios, engineering projects, or any situation requiring accurate on-site measurement — providing a flexible and efficient digitalization solution.

Discover Our Three Key Advantages

Flexible & Mobile

Our team can bring professional-grade equipment directly to your site, minimizing risks and avoiding the logistical challenges of transporting large or confidential items.

Broad Applications

Perfect for digitizing architectural components, art sculptures, and exhibition installations — ideal for items that cannot be moved.

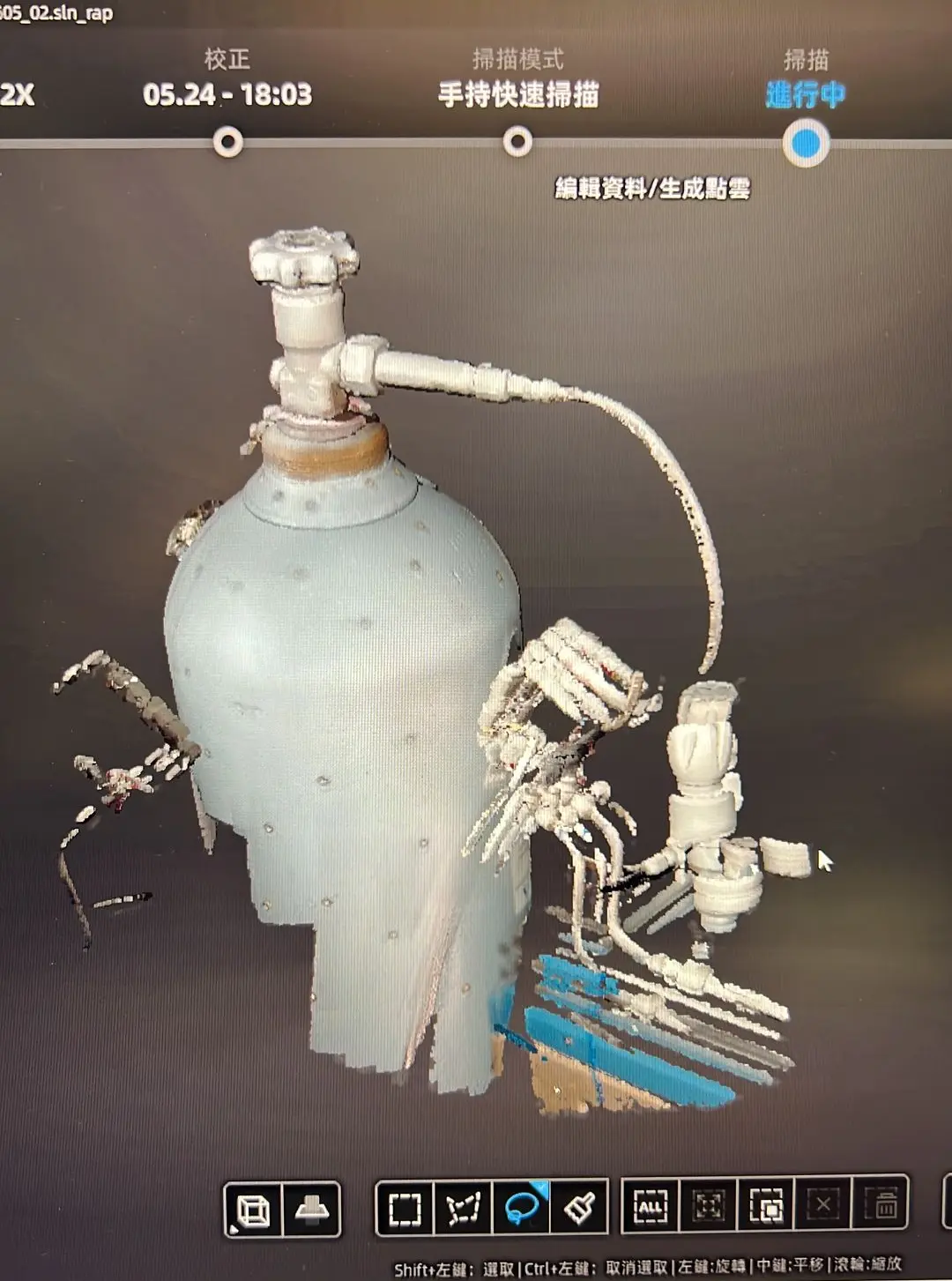

Real-Time Verification

Captured data can be reviewed instantly on-site, ensuring accuracy and completeness while preventing the need for rework.

Five Simple Steps to Completion

1

Initial Consultation

We confirm your scanning requirements, object size, and location details.

2

Schedule Appointment

We arrange an on-site session based on your preferred time and assign our technicians.

3

On-Site Setup

Upon arrival, we adjust equipment and lighting to prepare the scanning environment.

4

Data Scanning

High-precision 3D scanners capture complete and detailed model data.

5

File Delivery

Data is processed and delivered via cloud storage or physical media.

Tailor-Made Solutions for You

With our extensive experience in design and manufacturing, we help transform your ideas into reality. AIO Studio is committed to providing businesses and brands with reliable, high-quality, and efficient 3D production solutions. Contact us today to learn more or request a quotation.

Frequently Asked Questions (FAQ)

No. Our standard service uses the Shining 3D EinScan Pro2X scanner with precision up to 0.1 mm, much more accurate than consumer-grade devices. For jewelry or ultra-fine applications, our advanced scanners can achieve 60 microns (0.06 mm) point-cloud precision.

Clients are welcome to visit our studio to view sample scans and discuss details with our specialists.

For 3D printing, redrawing is usually unnecessary.

However, since scanners capture every surface imperfection (scratches, dents, etc.), redrawing is recommended when the model will be used for CNC machining or mold making, which requires clean geometric surfaces.

We also offer professional 3D redrawing services (quoted separately).

We typically provide .STL or .OBJ formats. Other file types can be supplied upon request depending on your intended use.

Yes, areas not reached by light may appear as small missing surfaces. Software will automatically repair these gaps, but a perfect match to the original is not always guaranteed.

Yes. Our on-site 3D scanning service allows us to come directly to your site for data capture.

Yes. We provide 3D printing, allowing clients to reproduce models at a 1:1 scale or modify them by resizing, editing, or painting.

For standard scanning, the maximum size is virtually unlimited — even large items like container trucks can be scanned.

The smallest workable object is approximately 1 × 1 × 1 cm, though fine details may decrease and may require manual retouching.

For even smaller parts, our ultra-fine jewelry-grade scanning can handle objects as small as 1 mm³. Contact us for specific inquiries.